To ensure greater consistency of your product, Morning Star has developed an improved means of identifying the finish for tomato paste and concentrated crushed tomatoes. These Morning Star Finish Standards of Identity use a set of photographs to classify the texture of the tomato paste being desired.

Traditional finish terminology is based on the size of the holes in the finisher screen through which tomato juice is passed. This may sound standardized, but the reality is something else. Factors other than hole size influence the amount of seed, peel, and other solid material passed through a screen, as described below, variation occurs for five main reasons:

1) Process: The volume rate at which the pulp is passed through the finishers and whether or not the pulp has been precooked changes finisher performance. Break temperatures affect finisher performance, as well as the use of pulpers prior to finishers.

2) Speed and pitch of rotor paddles: Rotor paddles act as both a centrifuge and a press, slinging and extracting the pulp into various tomato components: pomace and tomato juice. The speed of the rotor and flow rate of the pulp can vastly increase or reduce peel content relative to customer requirements. In addition, the “pitch” of the rotor paddles will either retain pulp in the screen for a longer or shorter period of time. Longer periods result in additional pressing of the pulp through the screen for a coarser finish while shorter periods result in an accelerated discharge of pomace through the finisher.

3) Type of equipment: Finishers separate juice and solid material differently depending on the screen manufacturer and the technology employed.

4) Variation in screen size: Some screen manufacturers punch their holes while others drill them, creating variation in the size of the holes.

5) Wear and tear: Over time, the screen wears, making the holes larger and dulling their edges. Finish varies depending on the timing processors choose to change the screen.

At its most basic level, tomato concentrating is the process of removing water, peel and seeds from tomatoes until a desired thickness is obtained. Evaporators remove water, while machines called finishers do the rest. The finisher separates tomatoes into juice and solid material (pomace). Pomace is a nutrient-dense mixture and is utilized in a multitude of ways, including soil amendments, animal feed and pet food.

Morning Star’s process for identifying finishes.

Paste is diluted to 8.5% NTSS and evenly spread on a white tray to allow careful examination of its insoluble solids content. The dilute sample is also placed in a standard Petri dish and photographed for record. The sample is then compared to customer specification to determine customer acceptability.

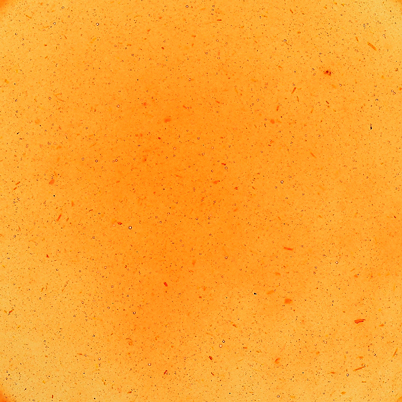

Typically .020–.033

Smoothest texture, no seeds, almost no pulp.

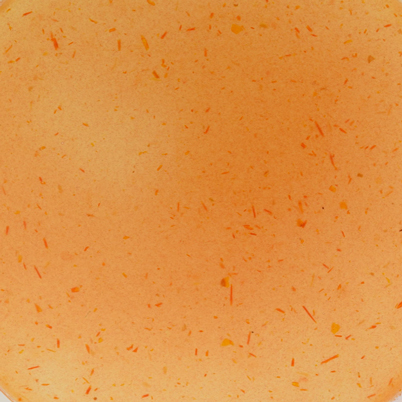

Typically .027–.045

Very little peel, no seeds.

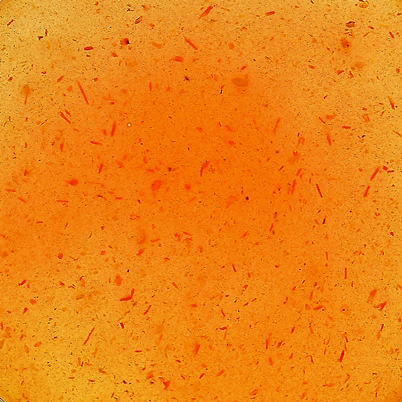

Typically .033–.060

Some flecks of peel and no seeds.

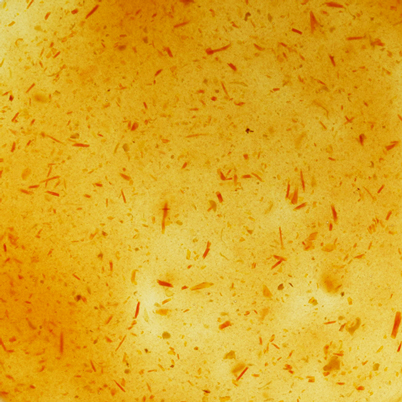

Typically .045–.060

Fair amount of peel and some seed pieces.

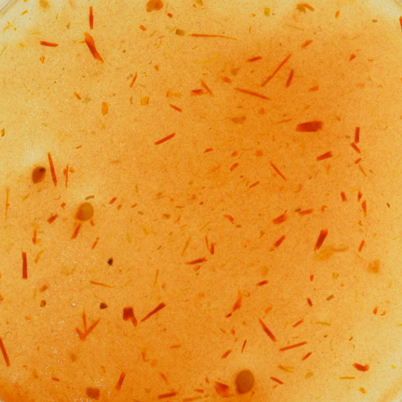

Typically .060–.078

Small lengths of rolled peel, some seed pieces and occasional whole seeds.

Typically .078–.090

Small lengths of rolled peel, some seed pieces and occasional whole seeds

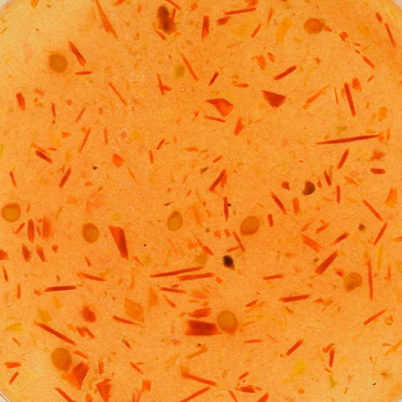

Typically .090–.125

Long lengths of peel (some > 3/8”), numerous whole seeds, and some pulp.

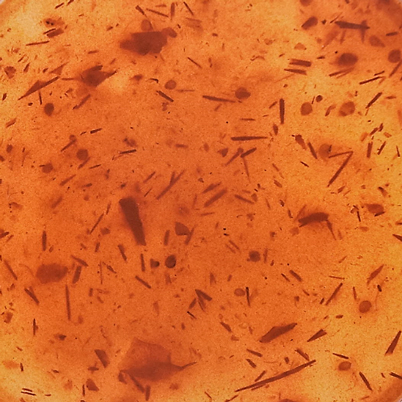

Typically .156–.250

Most of the tomato. Large pieces of peel (some > ½”), abundance of whole seeds, and chunks of pulp.

Our knowledgable sales and R&D team is here to help.

209.826.8000